Exploring the Impact of 3D Printing in Architectural and Product Design

As 3D printing continues to revolutionize architectural and product design, a new wave of creativity and innovation is sweeping through these industries. This article delves into the transformative power of 3D printing, highlighting its benefits and showcasing groundbreaking projects that push the boundaries of traditional design.

From intricate architectural models to cutting-edge product prototypes, the possibilities are endless with 3D printing. Let's embark on a journey to uncover the immense potential and endless opportunities that this technology brings to the fields of architecture and product design.

Introduction to 3D printing in architectural and product design

D printing has emerged as a game-changer in the fields of architectural and product design, revolutionizing the way designers and architects create prototypes, models, and even final products. This innovative technology allows for the fabrication of complex shapes and structures that were previously difficult or impossible to achieve through traditional manufacturing methods.The benefits of using 3D printing in architectural and product design are significant.

One major advantage is the ability to produce highly customized and intricate designs with ease. Designers can quickly iterate on ideas, test different concepts, and create prototypes rapidly, saving time and resources in the design process. Additionally, 3D printing enables the production of lightweight yet durable structures, opening up new possibilities for innovative and sustainable designs.The impact of 3D printing on traditional design processes cannot be overstated.

This technology has democratized the design process, allowing designers to explore new creative avenues and push the boundaries of what is possible. With 3D printing, designers can unleash their creativity without being constrained by the limitations of traditional manufacturing techniques.

As a result, we are witnessing a shift towards more innovative, efficient, and sustainable designs in both architecture and product design.

Applications of 3D printing in architectural design

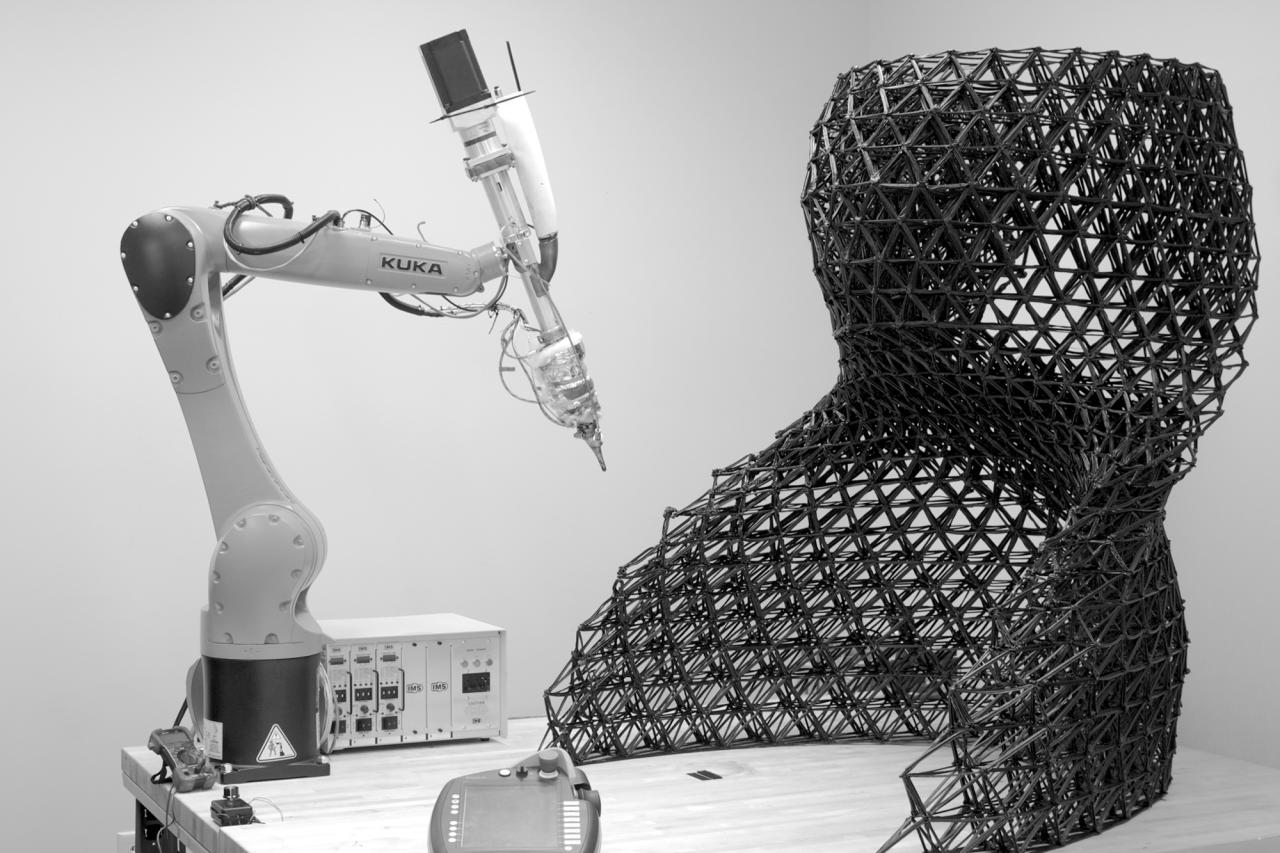

D printing has revolutionized the field of architectural design by offering a range of applications that were previously unimaginable. One of the key uses of 3D printing in architecture is the creation of detailed models and prototypes that allow architects to visualize and test their designs in a tangible form before construction begins.

Creating Architectural Models and Prototypes

D printing enables architects to transform their digital designs into physical models with intricate details and complex geometries. This technology allows for the rapid and cost-effective production of architectural models that accurately represent the final structure. By using 3D printing, architects can easily iterate on their designs, make modifications, and communicate their ideas effectively to clients and stakeholders.

- Architectural firms can produce scaled-down models of buildings, allowing clients to better understand the spatial layout and design features.

- Complex architectural elements, such as intricate facades or unique structural components, can be accurately reproduced using 3D printing technology.

- Architects can quickly create multiple iterations of a design to explore different possibilities and refine their concepts.

Advantages of Using 3D Printing for Complex Architectural Designs

The use of 3D printing in architectural design offers several advantages, particularly when dealing with complex and innovative designs that traditional manufacturing methods may struggle to realize.

- 3D printing allows for the production of custom and unique architectural elements that would be challenging or impossible to create using traditional methods.

- Architects can easily incorporate intricate details, organic shapes, and geometric complexities into their designs, pushing the boundaries of what is achievable in architecture.

- By utilizing 3D printing, architects can reduce material waste, optimize structural performance, and streamline the construction process by prefabricating components off-site.

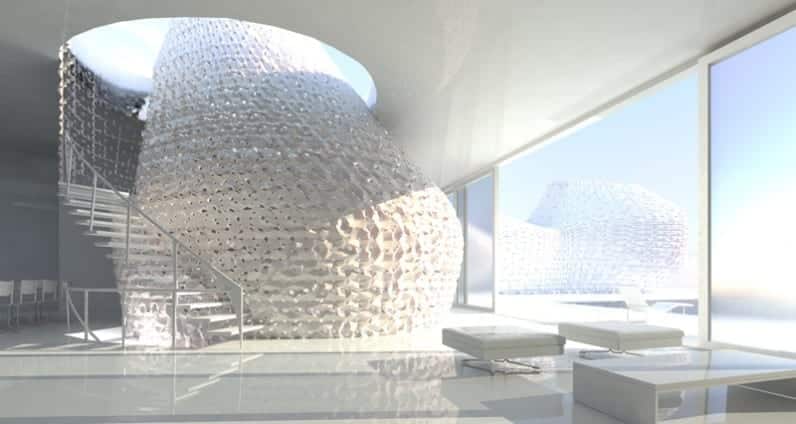

Examples of Innovative Architectural Projects Made Possible through 3D Printing

The application of 3D printing in architecture has led to a wave of innovative projects that showcase the technology's potential to transform the built environment.

- The MX3D Bridge in Amsterdam, created using robotic 3D printing technology, demonstrates the feasibility of printing large-scale metal structures.

- Organic forms and complex geometries featured in buildings like the Evolution Tower in Moscow highlight the creative freedom afforded by 3D printing in architectural design.

- Architectural firms like Foster + Partners have integrated 3D printing into their design process to realize intricate building facades and lightweight structures with optimal material efficiency.

Applications of 3D printing in product design

D printing has revolutionized the product design process by offering designers a more efficient and flexible way to bring their ideas to life. Unlike traditional manufacturing methods, 3D printing allows for the creation of complex geometries and customized designs with minimal material waste.

This technology has opened up new possibilities for product designers to experiment with innovative shapes, structures, and functionalities that were previously impossible to achieve.

Transforming the product design process

D printing streamlines the product design process by enabling rapid prototyping and iteration. Designers can quickly create physical prototypes to test and validate their ideas, allowing for faster feedback and design improvements. This iterative approach accelerates the product development cycle, reducing time to market and overall production costs.

Comparison with traditional manufacturing methods

Traditional manufacturing methods such as injection molding or CNC machining are often limited by the complexity of designs and high tooling costs. In contrast, 3D printing offers greater design freedom and cost-effectiveness, especially for low-volume production runs or custom products.

With 3D printing, designers can easily adjust designs on the fly and produce intricate, personalized products without the need for expensive molds or tooling.

Examples of successful products designed using 3D printing

- Nike's Vapor Laser Talon football cleat features a 3D printed plate that is lighter and more flexible than traditional cleat designs, enhancing player performance on the field.

- Airbus has integrated 3D printed components in its A350 XWB aircraft, reducing weight and fuel consumption while maintaining structural integrity and safety standards.

- Bespoke Innovations creates personalized prosthetic limbs using 3D scanning and printing technology, providing amputees with comfortable and aesthetically pleasing solutions tailored to their unique needs.

Materials used in 3D printing for architectural and product design

When it comes to 3D printing for architectural and product design, the choice of materials plays a crucial role in determining the quality, durability, and aesthetic appeal of the final printed object.The materials used in 3D printing can vary significantly, offering different properties and characteristics that cater to specific design requirements.

Let's delve into the various types of materials used in 3D printing for architecture and product design.

Materials for Architectural Design

In architectural design, 3D printing materials need to be sturdy, durable, and capable of producing intricate details. Some common materials used in architectural 3D printing include:

- Plastics: PLA (Polylactic Acid), ABS (Acrylonitrile Butadiene Styrene), PETG (Polyethylene Terephthalate Glycol), are widely used for creating architectural models due to their affordability and ease of use.

- Metal Alloys: Aluminum, titanium, stainless steel, and other metal alloys are used for creating structural components and intricate designs in architecture.

- Concrete: Specialized 3D printers can print with concrete, enabling the creation of large-scale architectural structures with intricate designs.

Materials for Product Design

In product design, the choice of materials for 3D printing is crucial to achieving the desired functionality, aesthetics, and durability of the final product. Some common materials used in product design include:

- Resins: Resins offer high detail and smooth surface finishes, making them ideal for creating prototypes and intricate products.

- Nylon: Nylon is a versatile material used for producing functional parts with high strength and flexibility.

- Metal Powders: Metal powders such as stainless steel, aluminum, and titanium are used for creating durable and high-quality metal parts in product design.

By understanding the properties and characteristics of different materials used in 3D printing for architectural and product design, designers and engineers can make informed decisions to achieve the desired outcomes in their projects.

Design considerations for 3D printing in architecture and product design

When it comes to designing for 3D printing in architecture and product design, there are several key principles and considerations that designers need to keep in mind to ensure successful outcomes. Understanding the design constraints that differ between architectural and product design is crucial, as well as optimizing designs for the 3D printing process.

Key Design Principles for 3D Printing

- Design for Additive Manufacturing: Embrace the additive nature of 3D printing by creating designs that take advantage of layer-by-layer construction.

- Optimize Support Structures: Consider the need for support structures in your design and optimize them to minimize material usage and post-processing.

- Design for Material Constraints: Understand the limitations of the materials used in 3D printing and tailor your design to work within those constraints.

- Consider Print Orientation: Think about the orientation of your design during printing to optimize strength, surface finish, and overall quality.

Design Constraints in Architecture vs. Product Design

- Architectural Design: In architecture, scale, structural integrity, and material properties play a significant role in design constraints. Large-scale printing may require different considerations compared to small-scale product design.

- Product Design: Product design often involves intricate details, moving parts, and specific functionalities that must be carefully considered for 3D printing. Tolerance, fit, and assembly are critical factors in product design.

Tips for Optimizing Designs

- Start Simple: Begin with basic shapes and structures before moving on to more complex designs to understand the capabilities and limitations of 3D printing.

- Use Proper Software: Utilize design software that is compatible with 3D printing processes and allows for easy modification and optimization of designs.

- Consider Material Selection: Choose the right material for your design based on its properties, such as strength, flexibility, and durability, to achieve the desired outcome.

- Test and Iterate: Prototype and test your designs iteratively to identify any issues early on and make necessary adjustments for a successful final print.

Last Point

In conclusion, 3D printing has undoubtedly changed the landscape of architectural and product design, paving the way for a future where creativity knows no bounds. As we witness the ongoing evolution of this technology, one thing remains clear - the only limit is our imagination.

Essential FAQs

How is 3D printing impacting traditional design processes?

3D printing is streamlining traditional design processes by offering faster prototyping, increased design flexibility, and cost-effective production methods.

What are some examples of innovative architectural projects created through 3D printing?

Projects like the Dubai Future Museum and MX3D Bridge showcase the incredible potential of 3D printing in architecture, pushing boundaries and redefining what's possible.

How does 3D printing compare to traditional manufacturing methods in product design?

3D printing allows for rapid prototyping, customization, and intricate designs that traditional manufacturing methods struggle to replicate efficiently.